Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

| Serial Number | Package | Spline | Material | Memo |

| B025 | 12pcss/carton | 23 | Aluminum alloy | manual |

| B025HP | 12pcss/carton | 23 | Aluminum alloy | manual |

| B026 | 12pcss/carton | 27 | Aluminum alloy | manual |

| B026HP | 12pcss/carton | 27 | Aluminum alloy | manual |

| B027 | 18pcs/carton | 19 | Steel | manual |

| B027HP | 18pcs/carton | 19 | Steel | manual |

| Serial Number | Package | Spline | Material | Memo |

| B022 | 18pcs/carton | 17 | Zinc alloy | manual |

| 18pcs/carton | Steel (strong) | |||

| B024 | 12pcss/carton | 20 | Steel | manual |

| B044 | 16pcs/carton | 24 | Steel | manual |

| B044HP | 16pcs/carton | 24 | Steel | manual |

If you want to know whether it can suit your car, you can contact us directly via the bottom ways.

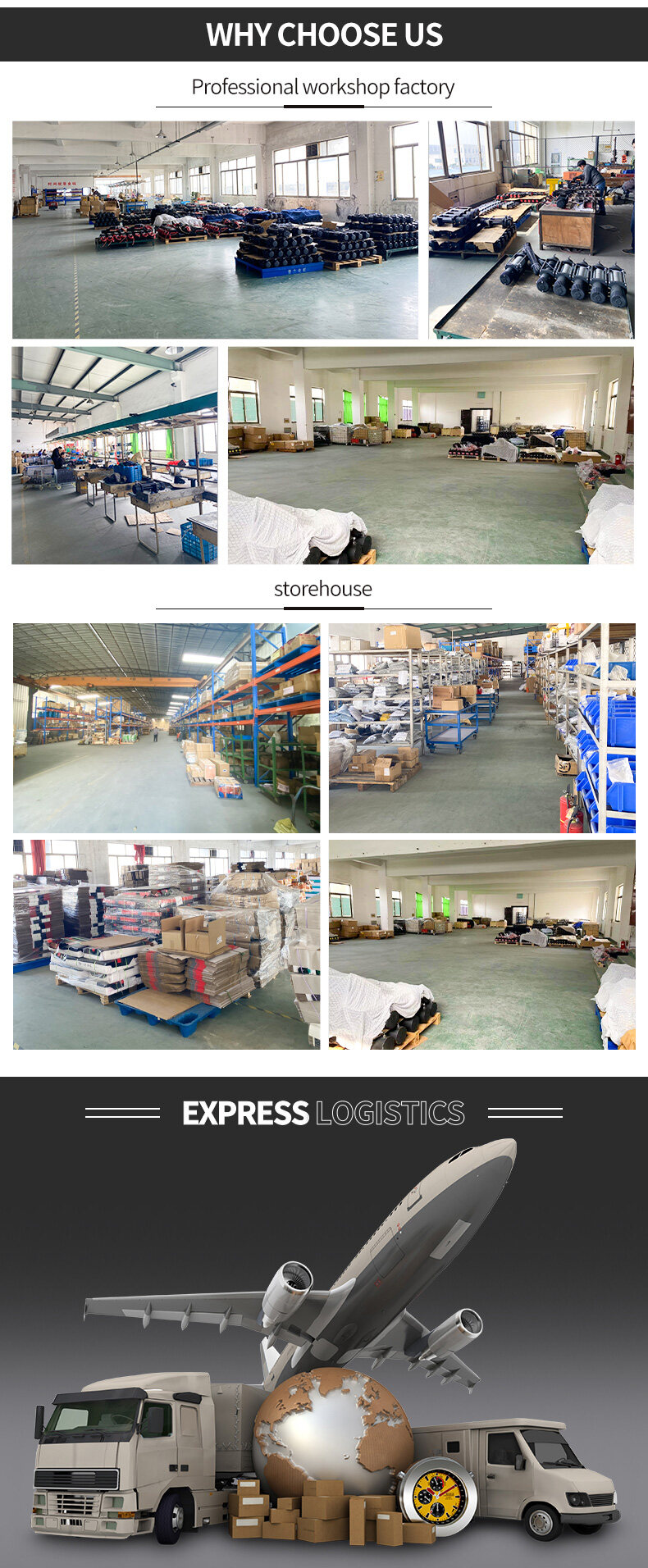

Auto-Cross country —— The best choice for field sport. WORKER is a highly specialised winch manufacturer situated in Ningbo, Zhejiang province, the most developed area in Changjiang, now the economic hub of China. Our premises cover an area of 16000 square meters, comprising more than 15,500 square meters of factory floor space and offices for our 100-plus employees. Our manufacturing plant has state-of-the-art assembly lines, together with in-house precision die-casting, CNC machining, heat treatment, polishing, high-pressure cleaning and finishing facilities.

We also have the most advanced, fully-automated intelligent electric motor and winch testing facilities in the winch industry, to ensure the very highest standards of product reliability and durability. Established in 2005,WORKER began a highly progressive and intensive R & D programme into winch design, using the very latest in technology, to improve product performance and efficiency in production. We currently own patents on our many improved winch design features and strive to maintain our unsurpassed build-quality and outstanding value.

Today, WORKER has a comprehensive range of winch products and is developing more, including the first in a series of efficient hydraulic winches, for the commercial and military markets. Our factory is currently producing 100,000 winches a year making us the one of the largest winch manufacturers in China. Winches which are exported to Europe, North America, Australia and many other countries, both in the guise of our own brand as well as OEM’s for many top names. Our philosophy is simple; to stay ahead in our business by being totally professional, but have fun doing it by remaining young in our hearts and minds.

We have passed CE CERTIFICATE, TUV CERTIFICATE, IATF 16949 CERTIFICATE, ISO14001:2015 CERTIFICATE and ISO9001:2000 CERTIFICATE.

Parts assembly - Finished product assembly - Inspection and testing - Packing into boxes

We support sea, air and land transportation, delivery to door point (refer to WE COULD BY SEA OR AIR OR DOOR TO DOOR SHIPPING). Products are generally shipped within 35 days, according to the product to provide bubble and carton packaging to ensure product safety.

Q: What is the MOQ?

A: Each product has different requirements, please contact us for specific products.

Q: What is your delivery time?

A: 35-40 days

Q: What is the payment method?

A: 30% PAYMENT AFTER CONFIRMED THE ORDER, 70% PAYMENT WHEN WE ARE READY TO SHIP.

Q: How do you guarantee the quality of the products?

A: We have strict factory testing to ensure the quality of each product.

Q: Are you a factory or a trading company?

A: The integration of industry and trade.

Q: Where is your factory?

A: Ningbo, if you want to visit, you can contact us.

Q: Are customized services available?

A: As long as you tell us your needs, we will provide you with customized solutions.

Q: Do you support OEM and ODM?

A: We support OEM and ODM services, if you need, you can contact us.

Q: Why choose us?

A: We are a professional manufacturer, focusing on the manufacture of 4*4 auto parts.

Strict inspection and testing process to ensure the quality of each product.

High-quality after-sales service to solve every problem related to auto parts.

Q: How long is the product warranty period?

A: 1-3 years.

What is a flywheel hub?

The free wheel hub is a bicycle wheel hub including a ratchet mechanism. A set of sprockets (called "flywheel") is mounted on the splined shaft of the flywheel to mesh with the chain.

What's the difference between flywheel and hub?

The hub is the main body in the center of the wheel, including the axle. It is more or less just some bearings in a pair of cups rotating around an axis.

The flywheel is a mechanism that locks when the pedal is pressed forward (forcing the wheel to be driven by the chain) and rotates freely when sliding or stepping back on the pedal.

Both wheels have hubs, but only the rear wheels have flywheels.

These are two variants of flywheel design, taken from the Wikipedia article linked above:

Older flywheel newer flywheel

On most modern bicycles with multiple gears, the flywheel is built into the rear hub, and the whole assembly is called the flywheel. The flywheel is just a set of gears bolted together without any moving parts. It slides onto the hub and is fixed in place with a lock ring.

On older bicycles, the hub is just a hub with some threads on one side. The flywheel is built into the rear gear set and the whole assembly is screwed to the hub.

Flywheel and flywheel to flywheel

Single speed bicycles are still (usually, despite changes) made like old bicycles, with flywheel and gear integrated and screwed to flower drums.

Cassette

Since its introduction in the late 1970s, flywheel has been used in many bicycles. Starting from the high end, flywheel can also be used in cheaper bicycles over time. Today, most derailleur bicycles use this newer design. On the flywheel, the gears are inserted into the flywheel body one by one. Then fix them in place with lock nuts. They range from seven gears to 12 speeds for high-end bicycles. Usually, they are installed on medium and high-grade bicycles to give riders more flexibility in terrain and provide them with more speed options.

Free wheel

The flywheel is a gear that is screwed directly onto the threads of the rear wheels. It does not need to be installed on the hub. It usually has 1 to 7 gears, and it is difficult to find a flywheel on modern bicycles. But you do find them on some new one speed bikes. The flywheel with one gear can also be fixed, which means that you must always step on the pedal unless the bicycle is stationary. although

Flywheel and flywheel

As mentioned above, the flywheel is a set of gears on which the chain is directly installed to drive the wheels. The ratchet system is built into the block, which means that the wheel can have only one set of threads on which the block is screwed.

However, freehub has no gears. It is the hub on the rear wheel, and the snap chain wheel slides onto it. This is a component with an internal ratchet system that locks when the box is driven by a chain causing the wheels to rotate.